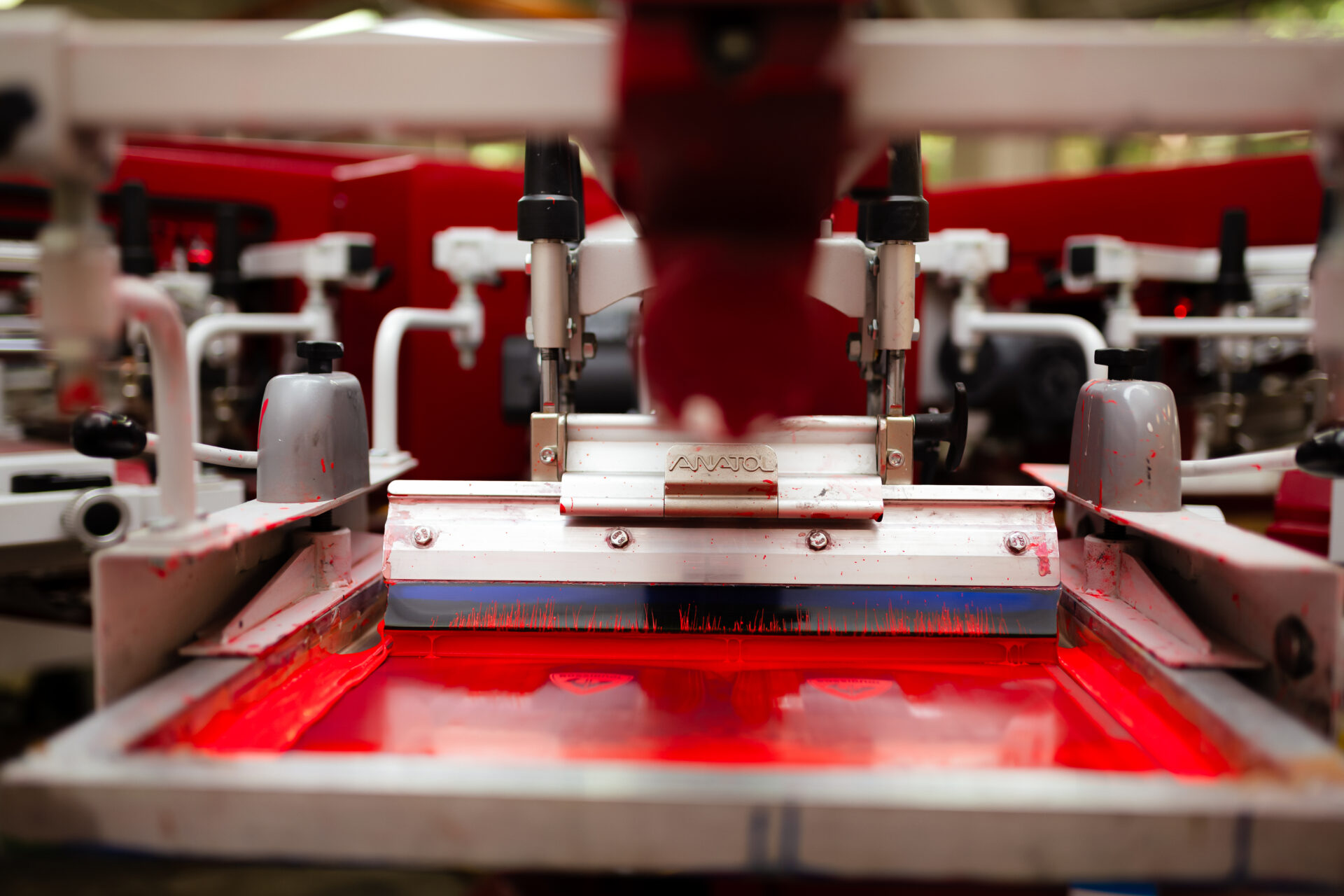

Screen printing is one of the oldest image printing processes on flat surfaces.

The process involves transferring a design onto the chosen material by applying a layer of ink using a pre-prepared screen and a special squeegee.

Although paper and textiles are the most common materials, this process can also be used on leather, PVC, metal, glass, and wood.

Antel Print has high-performance equipment that allows us to deliver high-quality industrial quantities on agreed deadlines.

3 automatic screen printing carousels capable of printing from 1 to 6 colors

1 automatic screen printing machine

3 semi-automatic screen printing machines

2 IR ovens

3 UV ovens

12 precision screen printing tables

Drying racks

Antel Print has high-performance equipment that allows us to deliver high-quality industrial quantities on agreed deadlines.

3 automatic screen printing carousels capable of printing from 1 to 6 colors

1 automatic screen printing machine

3 semi-automatic screen printing machines

2 IR ovens

3 UV ovens

12 precision screen printing tables

Drying racks

Production capacity of over 15,000 prints per hour

Quality control department

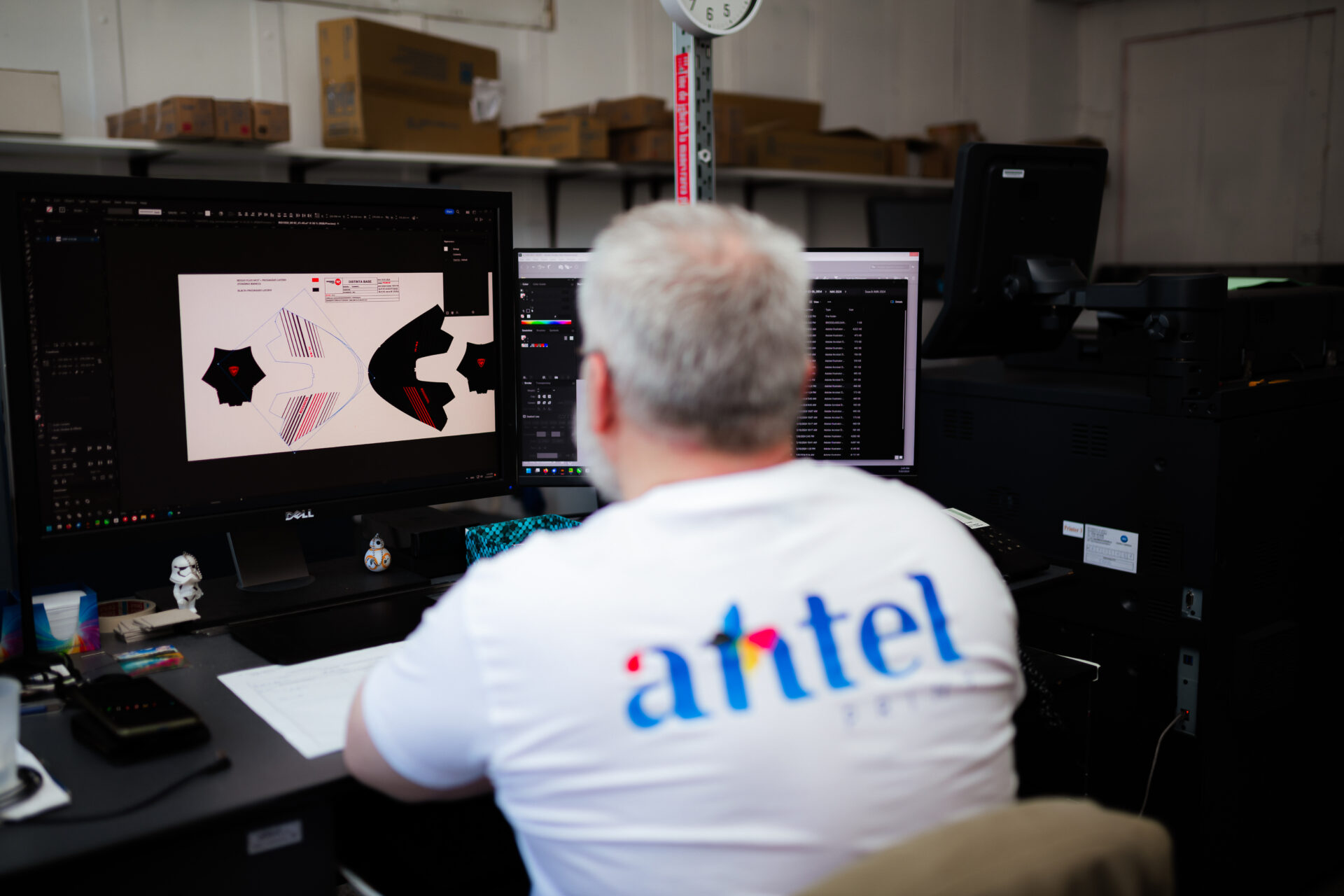

In-house screen printing and screen manufacturing department

Use of special inks that cannot be applied by any other printing process

Production capacity of over 15,000 prints per hour

Quality control department

In-house screen printing and screen manufacturing department

Use of special inks that cannot be applied by any other printing process

Production capacity of over 15,000 prints per hour

Quality control department

In-house screen printing and screen manufacturing department

Use of special inks that cannot be applied by any other printing process

Subscribe to our Newsletter

Phone:

0258 817 407

0358 101 028

Phone/Fax:

0258 817 407

Email:

antel@antel.com.ro